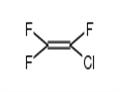

And especially when heavy friction or galling are possible for these metals. Due to their attack on the grease thickening agent, gaseous fluorine, hydrofluoric acid and caustic solutions are not recommended for use with FLUOROLUBE Greases. These CTFE Fluropolymer greases are transucent clear, flourinated synthetic, non-reactive, non-flammable, safe in chehemical and oxygen services and environments, fully saturated, hydrogen-free, low-molecular-weight oils made of Chlorotrifluoroethylene Polymer (CTFE). Detonation can occur when FLUOROLUBE Greases are allowed to contact these reactive metals free of their oxide coating in confined spaces and under heavy loads or high pressure. FLUOROLUBE Corrosion Resistant Oils & Greases - Perigee Direct Each shipment includes a complete Saftey & Technical Data Sheet 9002-83-9 - FLUOROLUBE GREASE, GR-362 - Sale from Quality Suppliers... APPLICATIONS Chemical Manufacturing Cryogenic Compressed Gases Electrical Applications – Dielectric Fluids Hydraulic Fluids Index Matching Fluids Instrument Fill Fluids Laboratory Apparatus Medical Applications – Life Support Systems Metalworking Nuclear Industry Pulp and Paper Industry Steel Industry Water and Wastewater Treatment Heat Transfer Fluids Thermal Stability: Thermal stability of the FLUOROLUBE Lubricants is between 300° and 600°F (150° - 315 °C) depending on the duration of heating and the materials of construction. FLUOROLUBE Lubricants may react violently with sodium and potassium metals, amines, hydrazine, liquid fluorine and liquid chlorine trifluoride. Certificates of authenticty included with purchase Comercio de los Fluoroproductos | AGC Chemicals Company FLUOROLUBE Greases consist of about 80% combined fluorine and chlorine and are nonflammable. Check out ou glass huicane pilla candle holde selection fo the vey best in unique o custom, handmade pieces fom ou candleholdes shops Thermal stability is affected by the presence of metals. Exposure to high temperatures will cause these products to depolymerize to lower molecular weight volatile compounds.