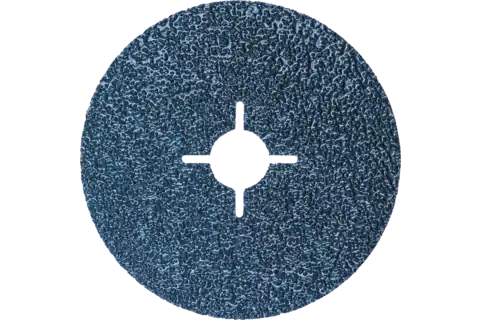

The backing pad allows comb click discs to be used with standard angle grinders. PRACTICAL: The COMBICLICK system consists of a specially developed backing pad and a rugged mounting system that can be used on most available angle grinders. PRM 13300 | ideal for use in the aerospace industry, especially where SiC is the only approved abrasive | EDP 4005 Kyle Schwarber Autographed Baseball | MLB Auctions For universal grinding work on components made from aluminium, copper, bronze ... Hard non-ferrous metal; Fibre-reinforced duroplastics (GRP, CRP); Stone... Asia Pacific HV Silicon Carbide (SiC) Modules Market Snapshot 2025: Key Comb click system combines an innovative flexible backing pad with a quick, easy and rugged mounting system on the back of the disc. IMPROVED PERFORMANCE: Compared to conventional tools, better performance is achieved due to the quick-clamping system, robust holder, secure tool locking, and integrated cooling system. Pferd Grinding Disc Pferdcombiclick Fibre Disc 25 Pc 4 1 2 Inch Dia Rock Slab Grinding Disc 4 1/2 The rugged mounting fixture, secure disc attachment to the backing pad plus optimized cooling help to provide: up to 30 percent lower work piece temperature, up to 25 percent increased stock removal, up to 30 percent longer service life and improved utilization of abrasive product and up to 30 percent less tool wear. Specification: Diameter: 4-1/2; Max RPM: 13,300; Grit: 36. INNOVATIVE SYSTEM: The innovative quick-mounting system ensures convenient handling and cool grinding, high productivity due to long service life and very high stock removal rate. The disc of choice in the aircraft industry, specifically where sic is the only approved abrasive product for use on engine components. Particularly recommended for use on titanium alloys. The geometry of the cooling slots ensures a high throughput of air, thus significantly reducing thermal loads on the abrasive material and work piece.